The stage LED display will encounter quality problems during use, causing the user’s display to be abnormal or even invalid. Every year, due to the quality problems of the display, the end customer’s complaints, deductions, returns, screen changes, etc., affect customer delivery, affect customer use, and affect their own payment recovery. The stage LED display has the following issues related to the kit:

① Black screen color is abnormal: color difference due to black screen due to the difference in the color of the kit mask.

② The mask is affected by thermal deformation: the material or size of the mask causes the mask to deform during thermal expansion and contraction, causing the mask to bulge and block the display angle.

③ Kit cracking: cracking and damage due to problems such as materials, glue, splicing, etc., outdoor products cause water leakage.

④ PCB anomaly: The open, short circuit, or via an abnormality of the PCB due to quality problems is open after the display is heated. ⑤ Other problems such as stitching effect and color cast are also formed on poor quality kits and PCBs.

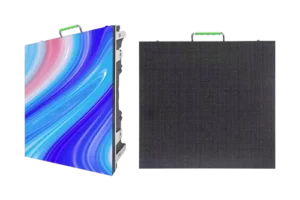

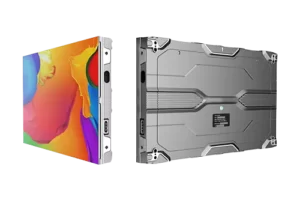

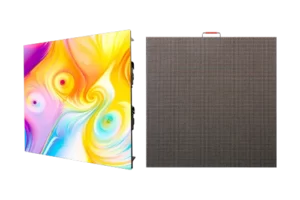

Shenzhen HTJ Technology Co., Ltd. was founded in 2015 with a registered capital of 50 million. It is a professional supplier of LED application products (indoor & outdoor LED displays, glass curtain wall transparent LED display, etc.), which integrates R&D, production, sales, and engineering services. In addition, it is also a professional application system solution service provider of LED products in China. Based on the forward-looking judgment of the LED industry and the accurate positioning of the company’s business strategy, HTJLED has become the fastest-growing enterprise representative in the industry. Thus, realized the development pattern of product characteristics, business comprehensiveness, and service specialization has been. The business covers LED light-emitting devices, LED application products product sales, application system solutions and engineering services, and other multiple links. We have our own unique insights into the choice of module kits. What is a good LED kit? In general, the superiority of the kit can be identified from the following aspects.

Size control

1. Dimensions: Whether the product is controlled according to the designed tolerance range. The product size is one of the important factors affecting splicing. The size control is good, and the product splicing effect will be good.

2. Thickness: The thickness of the product has a great influence on small-pitch or indoor products. When the display is spliced and installed, the difference in the thickness of the PCB and the thickness difference of the rear body will affect the flatness of the product. Therefore, it is necessary to select a kit and a PCB with a small difference in thickness in the selection of the kit.

3. Dimensional offset from the center of the lamp to the side: The dot pitch of a display screen is fixed. The dot pitch of the lamp face of the kit mask and the dimensional deviation of the PCB pattern is one of the important factors affecting the display effect.

4. If the PCB is abnormal due to the offset, it will cause problems such as partial lights.

Structure

1. Structural strength: The strength of the structure plays an important role in the deformation of the module and the use of splicing.

2. Structural practicability: whether it meets the needs of the module, is simple and practical, to solve – some small problems in production and installation.

3. The beauty of the structure is not a simple framework, is a product.

4. These aspects can be seen in whether a product is designed with care, in line with the products used in the display industry.

Process

1. In this respect, it can be seen that the surface treatment process of the PCB is.

2. The conventional surface treatment processes of PCB are: OSP, spray tin, sink gold, etc.

3. Generally speaking, the pad flatness of OSP and Shenjin is better. The OSP process has high requirements for the patch production process, and the pad bonding strength of the OSP process is poor.

4. The weldability of immersion gold and spray tin is better, but the flatness of the soldering pad is not good, and the thickness difference is large. After the patch, the height of the lamp will be different, especially in small-pitch products. Process.

5. In the cost of PCB from low to high OSP, spray tin, sink gold.

Material

1. The board material selected by PCB is FR-4 CEM-3.

2. The use of regular manufacturers of sheet materials, such as Shengyi, South Asia, Jianye (KB), international, and so on.

3. The grade of the selected sheet material is such as the construction of the 1.6A grade material, which is the structure of the 8-layer fiberglass cloth.

4. PCB deformation: good material deformation is good, generally controlled within 0.75%.

Coating thickness

1. LED PCB standard hole copper thickness is 18um±20% (excluding small pitch products below P2.5), and finished product line thickness is 35um±20%.

2. IPC PCB hole copper standard (thickness to diameter ratio is to guide the ratio of the diameter and thickness of the through hole).

3. Now the general quality PCB is controlled by the 2nd level standard.

4. The product aging below the level 1 standard: in use may cause abnormalities in the hole.

5. A lot of screens are just right when the point is right, but the temperature comes together abnormally, many times because of the copper problem.

Features

1. Normal display When selecting a product, it is necessary to perform functions such as verifying the display effect of the sample.

2. The high and low-temperature test function is verified by high and low-temperature test aging samples.

In order to meet the market demand for LED products, we will continue to improve the automation level of production technology and production equipment and continue to strengthen the market management awareness and service concept. Promote the application of LED optoelectronic series products in human green lighting in an all-around way.

About HTJ LED DISPLAY Shenzhen HTJ Technology Co., LTD. is a company that manufactures Transparent LED displays, LED creative screens, Dance Floor LED Displays, LED ball displays, LED video displays, LED curved screens, LED Stage Screen, cylinder LED displays, street light pole advertising, LED Display Panels, other custom LED displays and other high-definition LED full-color screens. It is a professional China LED display manufacturer integrating R&D, production, sales, and service.

The company is located near Shenzhen Baoan Airport, with a total area of 15,000 square meters, a production workshop of 10,000 square meters, and an office area of 2,000 square meters. With a large anti-static assembly line and SMD automatic surface mount equipment, wave soldering, and other technical equipment, the company relies on advanced management mode, strong technical research and development capabilities, and abundant raw material resources, and has carefully built a professional platform for modern enterprises.

Email: [email protected]

Language

Language