In recent years, the LED display industry has achieved a bumper harvest, small spacing LED occupied a large market share, and display product sales growth. At the same time, small spacing LED display technology is also making continuous progress — COB small spacing LED appeared on the stage, setting off a heat wave in the industry, leading small spacing LED into the “2.0 times”.

With the rise of COB technology, small spacing goes further

Comparing with different from the mainstream table sticking technology in the market, COB packaging technology first covers the LED placement point on the substrate surface with heat-conducting epoxy resin, and then heat treatment the LED until it is firmly on the substrate surface, followed by the use of wire welding to directly establish an electrical connection between the LED and the substrate, that is, binding chips on the plate. This new packaging technology makes LED display screen point spacing density a qualitative leap, arousing the interest of large screen enterprises.

At present, the fine pixel pitch LED Display core problem of is the same, all of which should be people-oriented, and related product development and application should be carried out around the interface problem. As a display screen, providing a more comfortable, color restoration of the good look and feel should be the same purpose. The progress of upstream LED chip technology has brought infinite possibilities for COB small-spacing display products, leading the development direction of the new generation of LED displays with a king posture.

Three advantages COB technology is favored

The rapid development of COB technology benefits from the resonance of the whole industrial chain and can get consistent support from the industrial chain, which is bound to have incomparable advantages. First, the COB does not require a table sticker, greatly improving the stability of the screen. The fatal injury of LED display products is the problem of dead lights because LED crystals are highly sensitive. In traditional production, the “reflow welding” process used for welding needs to be far higher than the 240-degree high temperature of the LED display screen, and the thermal stress changes in the high-temperature operation of the lamp bead, resulting in various problems such as life reduction and dead lamp. COB packaging technology abandons the table paste process, avoiding the damage of reflow welding to the lamp bead, so the dead lamp rate is only one-tenth of the traditional table paste. It’s distancing in terms of stability.

Secondly, LED display system has been widely used in various industries for their high brightness and bright colors. At the beginning of its development, it mainly focuses on outdoor long-distance viewing. With the wide application of indoor fields, the defects such as granulation of pixels, narrow display Angles, and visual fatigue are exposed in close and long-time viewing, which has become a big problem for the industry. COB surface light source technology softens and eases the visual display, realizing the transformation from a “point” light source to a “surface” light source, and making the picture uniform and free of pixel graininess. Surface plane + lamination technology can effectively control the brightness of the pixel center, reduce the light intensity radiation, and reduce the damage of more lines and glare to the retina, and it is not easy to produce visual fatigue in close and long viewing environments. Compared with traditional LED screens, COB is more suitable for meeting rooms, dispatching centers, and other scenarios.

On the other hand, COB technology is chip-level packaging, using integrated processes. LED crystals are connected directly to the substrate, both in front and back. This increases the heat transfer area of LED crystals, greatly improving the heat dissipation capacity, which is conducive to maintaining a constant temperature during the system operation and prolonging the lamp bead life. At the same time, epoxy resin is fully wrapped to put on a layer of 100% durable “armor” for LED crystals, which can effectively avoid transportation and daily use of bumps, be waterproof and moisture-proof, and improve the reliability of display products.

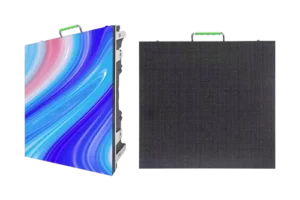

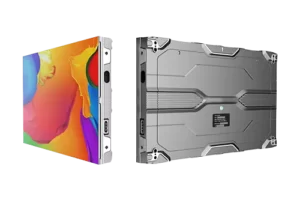

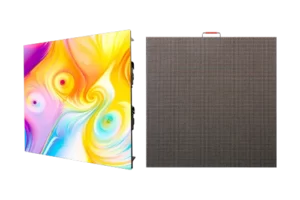

Shenzhen HTJ technology co., LTD. is an LED display manufacturer from Shenzhen, China, whose products are exported to more than 200 countries . The main production of Small Pixel Pitch LED Display models is LED product models of P2.5, P2.0, P1.8, P1.5, P1.25, P1.0, P0.9, etc, they are mainly characterized by:

1. It has a single box weight of only 6kg, a thickness of only 60mm ultra-thin features

2. CNC fine scientific digital processing, error less than 0.1mm, truly seamless splicing

3. Brightness adjustable range of 800-1200 – CD, 160 °, 150 ° angle of view, much more clear images can be seen from the left and right sides of the screen and the up and down direction.

4. Extremely high color consistency, no local distortion, lack of brightness, and other phenomena

5.16bit gray, high contrast, high refresh rate, fine quality, smooth, high fidelity

At the same time, it also has a reception card, wiring board, and power supply that can be maintained in advance. It reduces the difficulty of product maintenance, solves the worries of customers, and the advantages of easy assembly of 1080P, 4K HD large screen, and 16:9 golden ratio of the box.

Never stop to face the future and lead to new breakthroughs

Due to the late start of COB technology, the accumulation of process technology and material technology in the field of small-spacing LED display is less than that of SMD technology, and COB small-spacing LED is currently mainly applied in the “high-end indoor command and dispatch” system, which has a low popularity among the public. However, the general trend of COB has been very clear, as an emerging technology, from the high-end market segment to popularization is a necessary process. With technological innovation, we believe that COB technology will break the bottleneck and bring new breakthroughs for the development of small spacing.

About HTJ LED DISPLAY

Shenzhen HTJ Technology Co., LTD. is a company that manufactures Transparent LED displays, LED creative screens, Dance Floor LED Displays, LED ball displays, LED video displays, LED curved screens, stage LED displays, cylinder LED displays, street light pole advertising, LED Display Panels, other custom LED displays and other high-definition LED full-color screens. It is a professional China LED display manufacturer integrating R&D, production, sales, and service. The company is located near Shenzhen Baoan Airport, with a total area of 15,000 square meters, a production workshop of 10,000 square meters, and an office area of 2,000 square meters. With a large anti-static assembly line and SMD automatic surface mount equipment, wave soldering, and other technical equipment, the company relies on advanced management mode, strong technical research and development capabilities, and abundant raw material resources, and has carefully built a professional platform for modern enterprises.

Language

Language