As we all know, for Mini LED Screen Display, contrast is one of the important parameters. The greater the contrast, the clearer the image and the brighter the color. The contrast of Mini LED Screen Display screens on the market are very different, and the value is often different by several digits.

Why is the contrast so different?

According to the calculation formula of contrast: Contrast=Brightness when emitting light (luminous brightness)/Brightness when not emitting light (reflective brightness). “Bright”, and reduce the light reflection coefficient on the surface of the display screen, making “black darker”.

In practical applications, there are many factors that cause the contrast difference of the small-pitch Mini LED Screen Display.

The size of the chip is different, the smaller the chip used, the higher the contrast of the LED display.

Under the same dot pitch condition, the smaller the LED chip size, the larger the black area, and the lower the brightness when not emitting light. Although the light emitting area is reduced, the contrast ratio is greatly improved. This is currently the most direct and effective way to improve contrast. Under the premise of the same dot pitch, the smaller the chip, the larger the “leave black” area, which can make the overall display “blacker and darker”

A formal chip is different from a flip chip, and the contrast of a flip chip will be better than that of a formal chip.

In a formal LED chip, the electrodes and bonding wires are on the light-emitting surface, occupying a part of the area that should be light-emitting, which will affect the light-emitting angle and luminous intensity of the LED chip to a certain extent; and the metal components such as the electrodes and bonding wires are also It will cause reflections, make it “dark when it should be bright”, and reduce the contrast of the display.

Flip-chip, no electrodes and bonding wires to block and reflect light, large light-emitting area, luminous efficiency is significantly better than that of formal-mounted chips, so that “brighter and brighter”, the contrast is usually higher than that of formal-mounted chips.

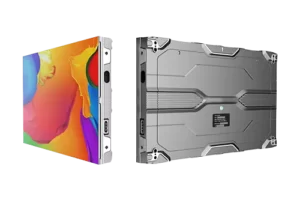

In the case of the same COB packaging method, the flip-chip structure has a larger light-emitting area

SMD and COB packaging methods are different, and the contrast ratio of COB packaging products is often much higher than that of traditional SMD packaging products.

SMD LED displays need to use a support structure to support chip devices. However, due to the size limitation of the bracket, the package body using the SMD bracket cannot continue to shrink, and there is a physical limit for the RGB light-emitting pixels. The large area of the light-emitting point means that the “black area” on the surface of the Mini LED Screen Display is small, and it cannot make the “black blacker”, resulting in low contrast of the LED display.

p1.56-LED-Dsiplay-768×576.jpg

The COB packaging method does not have a support structure, so with the support of Mini/Micro LED chip technology, display manufacturers can use smaller chips according to different viewing needs. The smaller the chip area on the PCB board, the larger the black area, the brighter the black area of the Mini LED Screen Display, the darker the black field, the brighter the brightness, and the higher the contrast of the Mini LED Screen Display.

In the case of the same size of chip, the structure of the COB and the distance between the light-emitting pixels are better than those of the SMD package

The brightness of early LED chips was insufficient. When the chip is applied to the SMD display, a white bracket is needed to enhance the focus reflection and increase the brightness of the display, but this also loses the black area, accompanied by the loss of display color expression and low contrast. problem.

Later, as the luminous intensity of LED chips became higher and higher, display manufacturers began to use black bracket SMD, or add a black layer on the luminous surface to make “black blacker” and increase the contrast to meet the audience’s demand for image fidelity. . However, there is also a color difference between the black of the bracket itself and the black when the LED is turned off, and the overall contrast enhancement effect is limited.

The COB packaging method does not have a support structure, so its contrast is not affected by this factor and can be maintained at a high level.

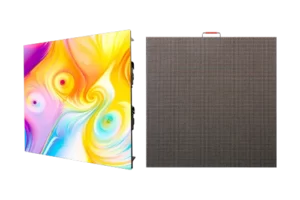

The difference between black light SMD and white light bracket SMD

Different contrast measurement methods will also have a great impact on the contrast data. Basically, contrast is also divided into static contrast and applied contrast.

Static contrast is the highest contrast of the screen measured in a dark room environment. Generally speaking, due to the extremely high brightness of LED display screens in a dark room environment, the static contrast ratio is often as high as tens or even millions to one.

Application contrast refers to the highest contrast of the screen measured under an ambient illuminance of 10±10%lx. According to industry standards, the application contrast ratio of Mini LED Screen Display screens is greater than or equal to 5000:1, which is the highest level C. The application contrast ratio of HTJLED‘s unique ink color “Ice Jade Black” is as high as 15000:1, which is 3 times the industry standard, and the display effect is vivid and realistic.

In summary, it can be seen that miniaturized LED chips combined with full flip-chip and COB packaging are of great value in improving the contrast of the display screen. With the support of Mini/Micro LED chips, a full-flip COB display will be the best solution for high-contrast and small-pitch LED displays.

Language

Language